SOFCA srl has designed a family of wireless wrenches capable to perform the objectification control and to acquire information about the tool status, the tightening parameters, any sequence of objectification, the number of cycles and the level of the battery charge.

SOFCA srl has designed a family of wireless wrenches capable to perform the objectification control and to acquire information about the tool status, the tightening parameters, any sequence of objectification, the number of cycles and the level of the battery charge.

Tightening strategies:

- Torque with time control

- Torque with angle and time control

- Torque and Angle

- Angle with time control

- Angle with torque control

- Angle with torque and time control

The wireless control unit is available in the following versions:

- 1 channel

- 2 channels for two operators to work simultaneously

In the two-channel version, the control unit supports any combination of COIL, ILCO, Riveter, Torque Wrench tools:

| CH1 | CH2 | |

| Torque Wrench | + | Torque Wrench |

| Torque Wrench | + | ILCO |

| Torque Wrench | + | Riveter |

| Torque Wrench | + | COIL |

Technical characteristics:

- Torque: peak or continuous mode reading

- CW e CCW

- 9x12 and 14x18 push-in connector

- Torque accuracy reading: 1% (10% -100% of full scale)

- Angle measurement accuracy: 1 ° over 360 °

- Rechargeable battery power supply via dedicated battery charger

- Auto power off

- Units: Nm

- Data memory: 1000 (date, torque value, angle value, measurement set)

- Warning by three led blue / green / red

- 3 lights with 360 ° visibility

- Six control keys

- Display 120 x 32 pixels

- Serial communication via RS232C, Ethernet, Profinet (Optional PC connection kit)

- Function control by menu

- Breakaway torque (optional)

- Compliant with the requirements of UNI-EN-ISO 6789-2004

- Torque or torque/angle reading

- Continuous operation autonomy: 12 hours

- Ring light intensity adjustment from 1 to 5 via control unit command

- Possibility of downloading data onto a USB stick

- CM-CMK or similar calibration certificates

- Wrench calibration certificate with ACCREDIA reference

- TOCS SUITE software for data processing that can be installed on any PC or multiple workstations

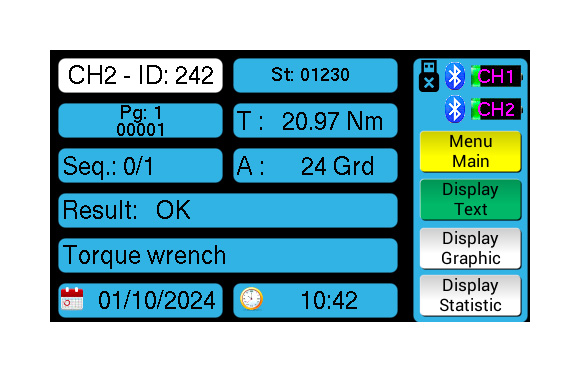

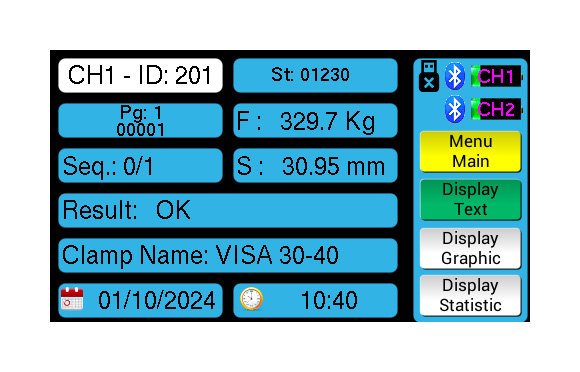

Display 120 x 32 pixels

Selection of super light carbon wrenches SOF-CARB series

Mechanical characteristics

| Model | Code | Length mm | Width mm | Hight mm | Nm | Weight gr | Connection | Drive |

| SOF_TG 50 | SOF 260050 | 356 | 62 | 54 | 50 | 710 | 3/8” | 9x12 |

| SOF_TG 100 | SOF 2600100 | 416 | 62 | 54 | 100 | 830 | 1/2” | 9x12 |

| SOF_TG 200 | SOF 2600200 | 514 | 62 | 54 | 200 | 950 | 1/2” | 14x18 |

| SOF_TG 350 | SOF 2600350 | 606 | 62 | 54 | 350 | 1100 | 3/4” | 14x18 |

CHARGER

WORKBENCH

SPECIAL INSERTS FOR TORQUE WRENCHES