The SICO System is a product that satisfies all the visual marking requests, allowing the traceability of the tested element, during the various phases of a production process.

The SICO System is a product that satisfies all the visual marking requests, allowing the traceability of the tested element, during the various phases of a production process.

The product takes very little time to install, is highly simple to use and essentially maintenance free, meaning that the initial investment is quickly recouped.

The disposable cartridges are easy to replace and after a cartridge change the system is immediately ready for use, without any need for adjustment.

You can choose among a range of already available colors; in the case of special requirements, new colors may be created for sufficiently large quantities.

This spray stamping system with ecological paint allows to objectify and / or identify in a visual way the production of components produced on assembly lines, be they in iron, steel, plastic, rubber, wood, glass or whatever.

The advantages of our standard marking system are:

- Installation time and start-up: 5-10 minutes

- Immediate programming

- Cartridge change in seconds

- Transition from one color to another in seconds without the need to clean the nozzles

- In case of stop production for days or weeks, the system does not require cleaning of the ducts or nozzles

- It is extremely clean, no drips or paint stains on the mechanical parts around the area of marking

- This system is also used when the counting of good/rejected pieces are carried out by methods such as: barcode, STATEC, computer memory or other, since the paint spray provides immediate traceability and increased visibility of the outcome good/no good both at the manufacturing plant, and at the end user site.

For each SOF SICO Marking System, a pneumatic group must be installed, made of:

- Pressure reducer to 4-6 bar

- Pressure gauge

- Water separator

- Air filter

- On-Off valve

To optimize the result of using our system it is necessary to pay maximum attention to the points highlighted below:

- Proper nozzle-assembly distance between 5 and (maximum) 15 mm

- Correct installation with an inclination of the marker greater than 15 degrees with respect to the horizontal plane

- Quality of used valve

- Length of the supply pipe

- Supply pressure

- Nozzle used

- Cartridge life

- Used colors

Storage of the cartridge packages

Rules of storage of cartridge boxes:

- Each pack contains 10 color cartridges

- The weight of each individual new cartridge is equal to 62 grams ± 2%

- The weight of an empty cartridge is about 52 grams

- Store in a cool, dry place

- During storage it is important to place the package in a vertical position, as indicated by gray triangles on black background of the pack (The tip of the paint must be always down)

- We suggest a use within 2 months from the date printed on the inside cover of each package (or the date of the Transport Document)

- If the storage climate and weather conditions are favorable (e.g. temperatures between 18 ° and 26 °, not very dry climate, etc.), in these cases the use of cartridges can last up to four months and beyond.

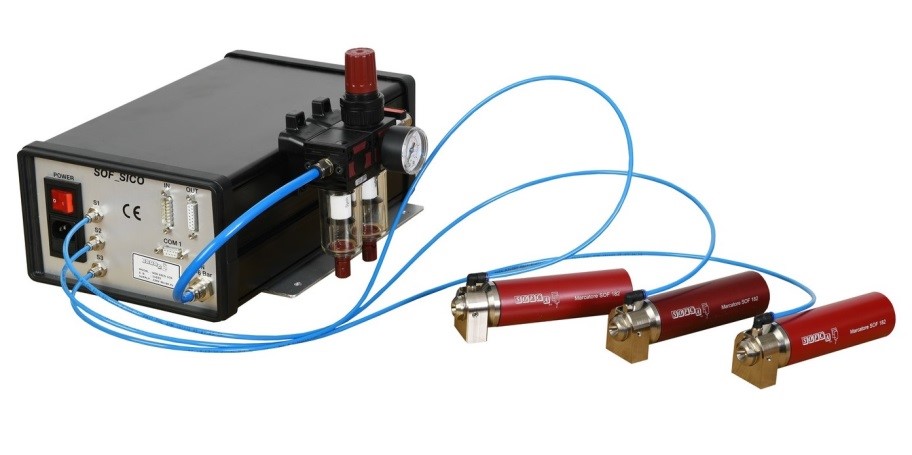

The SPM 100 SOF-SICO Control Unit

Sofca srl, after a careful study of the problems related to paint marking and many experimentations carried out in its laboratory, has developed a control system for the control of the SOF-SICO MARKER named SPM 100 SOF-SICO.

With the creation of this system we believe we are in the optimal condition to be able to offer our customers a complete service, with maximum efficiency.

With our turn-key system you can install the entire marking system quickly and easily, because all you need is integrated and compacted in our SPM 100 SOF-SICO, as detailed below:

- microprocessor system able to handle up to a maximum of 3 SOF-SICO MARKER

- integrated solenoid valve(s) with high power intervention

- built-in air treatment unit complete with: pressure gauge, pressure reducer, filter, water separator, and ON-OFF valve

- optional printer for cycle objectification

- able to be set either manually and by PLC

- programming logic:

- choice of ITALIAN / ENGLISH language, you can enter other options on request (Spanish, German, French, etc.)

- time programming in milliseconds

- cycles setting for cartridge change

- notice to PLC for cartridge out

- ability to report the end of the cartridge and any result by acoustic method (buzzer) and/or visual method by a three-light device (as a traffic light)

- print report of the performed cycles along with data

- diagnostics for manual activity

- debugging, i.e. the activity that allows the technician to identify, in a timely and simple mode, the right parameters for each type of items to be marked