The system EVT_COIL (Electrical Visa Tool Control Objectification Integration Line) was designed and built by SOFCA s.r.l. to objectify and control the tightening of the VISA® clamps produced by company  .

.

The system EVT_COIL (Electrical Visa Tool Control Objectification Integration Line) was designed and built by SOFCA s.r.l. to objectify and control the tightening of the VISA® clamps produced by company  .

.

The system is produced in two versions depending on the interface used to communicate with the Control Unit:

- Link wireless Bluetooth (model EVT_COIL_W)

- Connection with cable (model EVT_COIL_C)

The control unit, both in wireless and “wired” version, is available in the following versions:

- 1 channel

- 2 channels for two operators to work simultaneously

In the two-channel version, the control unit supports any combination of COIL, ILCO, Riveter, Torque Wrench tools:

| CH1 | CH2 | |

| COIL | + | COIL |

| COIL | + | Torque Wrench |

| COIL | + | ILCO |

| COIL | + | Riveter |

The solution with the tool connected by cable is used when the electromagnetic environment is hostile or when the tool has to be installed in an automated station.

The EVT COIL system is able to check the proper tightening, count the number of clamps that make up the assembly cycle, check that the assembly sequence was properly followed and transfer the data to a storage system based on the use of a PLC, PC, PFCS, ETHERNET NETWORK.

The 'objectification' term refers to the process by which an intelligent equipment is programmed to monitor the activities of an operator while performing a sequence of assembly; the intelligence of the equipment lies in its ability to control and verify the same sequence during the production.

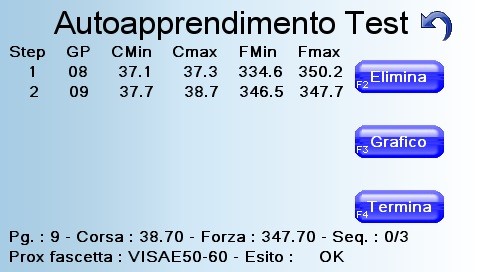

The objectification of the tightening is optimized with the self-learning procedure, which determines the values of the parameters related to the control of the clamp tightening while giving the technologist the possibility to analyze and correct these values.

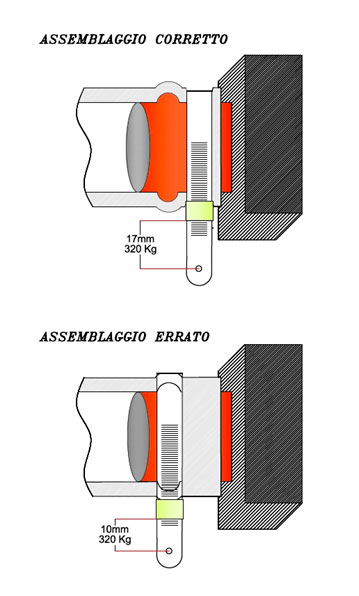

During tightening, the band is guided by a stainless steel clip with non-return ratchet-like teeth which allows the band to slide in the direction of tightening but locks it in the direction of loosening. The tail end has a stamped rack and a stamped protrusion (pip) engineered to a pre-determined shearing force that provides a calibrated clamping force. When the pip is cut, in its place there is a hole.

The shearing of the pip would indicate that the proper force has been applied to the clamp, but the COIL system gives the confirmation of such force, and hence validates or not the correct tightening of the clamp according to the parameters set by the self-learning procedure.

The EVT_COIL system gives the best guarantee on the VISA® clamp tightness by applying the following strategies:

- Self-learning for setting parameters that ensure a good tightening

- Detection of the parameter values is in real time, during the tightening process, by reading the sensors

- Data processing and decision based on the outcome of the tightening

- Event outcome as a graphic on the control unit, switching-on of the traffic light on the tool, print out of the results, release of the data on PLC/PC or remotely over Ethernet, when requested

- Scheduled maintenance supported by the control unit which, on the basis on the number of cycles implemented, will warn the operator

Characteristics of the EVT_COIL system:

- Practical system, since there are no cables and hoses to drag

- Reduced tool weight, about 2 kg

- Maintenance limited to the replacement of the cutter and socket

- Long autonomy of the battery, on average you get about 1400 tightenings of the larger VISA®, those employing more power

- Change of the battery in about 4-5 seconds

- Time of about one hour to charge the 18 VDC lithium battery with the convenience of having the second battery charging

- Graph of Force vs. Stroke with indications of their acceptability thresholds after cycle performed

- Adjustment of the intensity of the ring light from 1 to 5 by means of a control on the Control Unit

- Flexible interface for monitoring, remote control, uni and bi-directional data exchange

- Availability of an on-site bench for the verification of the tightening force through the use of a load cell certified by ACCREDIA laboratories

The EVT_COIL products are controlled and qualified in the factory on test benches which are operated:

- Manually, with an instrumented bench for the characterization of the physical magnitudes operating in the tool

- Automatically, by a device assisted by the control unit, which provides the mechanical reaction to the tractor, for the running-in tests

The EVT_COIL system, in its basic version, consists of:

- Wireless Control Unit

- EVT_COIL tool with LEDs at 360 degrees

- No 2 batteries

- Battery-charger

- EVT_COIL containment support

Upon request, Sofca can provide the EVT_COIL system arranged as "operating station" and configured according to the customer needs; the station, in its typical configuration, consists of:

- Bench with anodized aluminum frame

- Tool with the LEDs for successful operation and warnings

- Control Unit with optional 360 degree beacon

- Dedicated printer for timely report of the operations

- Barcode device to select the appropriate control parameters (the programs can be selected via barcode and taken in charge by the system automatically)

- Program selector GPBOX