For over 25 years, SOFCA srl is active in the production, maintenance, testing, process quality control, design and construction of technologies and systems in the automotive market. To this basic orientation, the company has added a specialization in technical assistance on private industrial fleets and public transport with two technical centers (MI and TO) with CNG/LPG retrofit services, replacement and overhaul of gas tanks of all types and sizes, computerized diagnosis.

For over 25 years, SOFCA srl is active in the production, maintenance, testing, process quality control, design and construction of technologies and systems in the automotive market. To this basic orientation, the company has added a specialization in technical assistance on private industrial fleets and public transport with two technical centers (MI and TO) with CNG/LPG retrofit services, replacement and overhaul of gas tanks of all types and sizes, computerized diagnosis.

Legend

| Battery | Current value of the battery voltage; on the side is the same value as a percentage of the nominal value |

| Pressure | Current value of the pressure; on the side is the same value as a percentage of the nominal value |

| Autonomy | Evaluation of the distance that the vehicle can take under the current conditions of filling the gas cylinders |

| Oscillation | Current value of the pressure variation in the system; one of the parameters monitored by the CTL is the internal pressure of the BCNG system which is sampled in real time and which must not exceed a maximum oscillation value |

| OK:… | Space reserved for reporting anomalies and warnings |

Maintenance

For the scheduled maintenance of the BCNG bench, in addition to the periodic replacement of the final fitting, the following operations are required:

- system tightness check, once a month, by means of a special electronic nose to search for gas leaks

- cylinder check, every 4 years it is necessary to periodically check the cylinders at an inspection center

Sofca is available to check the tightness of the cylinder system at one of its inspection centers.

Storage

When the system is not in use, it is advisable to store the BCNG bench in an open room with a suitable cover from above, this to prevent possible risks in the event that the procedure for emptying the tubing of the BCNG bench is not scrupulously carried out at the end of use.

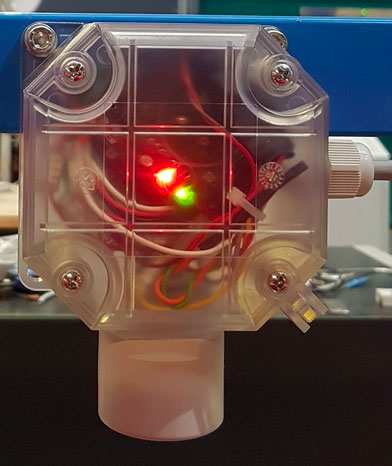

Gas leak detector

The gas leak detector activates on two alarm levels:

- Pre-alarm when the gas concentration in the environment reaches the level of 50% LEL (Lower Explosive Limit)

- Alarm when the concentration reaches 100% LEL

Both the overruns of the limits, pre-alarm and alarm, are shown with audible and visual signals on the control unit, on the tablet and on the detection device itself.